Quality Policy

Precision Measurement. Assured Quality. Superior Products for Mutual Success.

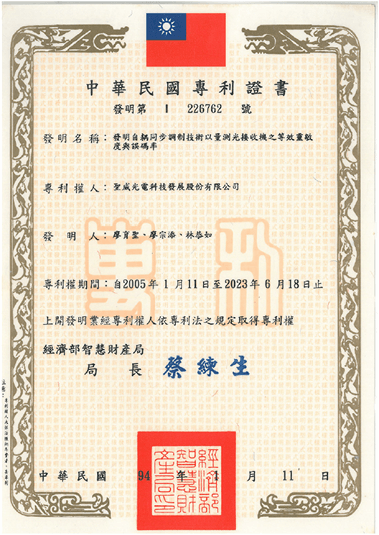

Quality starts with precision measurement and stable processes. Through rigorous management systems, we ensure every product meets high-performance standards.

We leverage ERP and MES systems for batch control and real-time process data tracking, monitoring each stage—from incoming material inspection to final delivery—to enable comprehensive traceability and end-to-end quality assurance.

These integrated systems enhance reliability and provide production transparency and documented product histories, reinforcing trust in quality and safety. We drive continuous improvement and long-term partnerships to deliver reliable, win-win outcomes.

Five Core Quality Tools

SPC

Statistical Process Control

Continuous monitoring and improvement of process stability through data-driven statistical analysis.

MSA

Measurement System Analysis

Evaluates the accuracy and consistency of measurement systems to ensure the reliability of inspection results.

FMEA

Failure Mode and Effects Analysis

Identifies and mitigates potential failure risks to optimize product design and manufacturing processes.

APQP

Advanced Product Quality Planning

Ensures quality is built into new product development through structured planning and early-stage evaluation.

PPAP

Production Part Approval Process

Verifies that the production process meets all customer specifications through rigorous qualification and documentation.

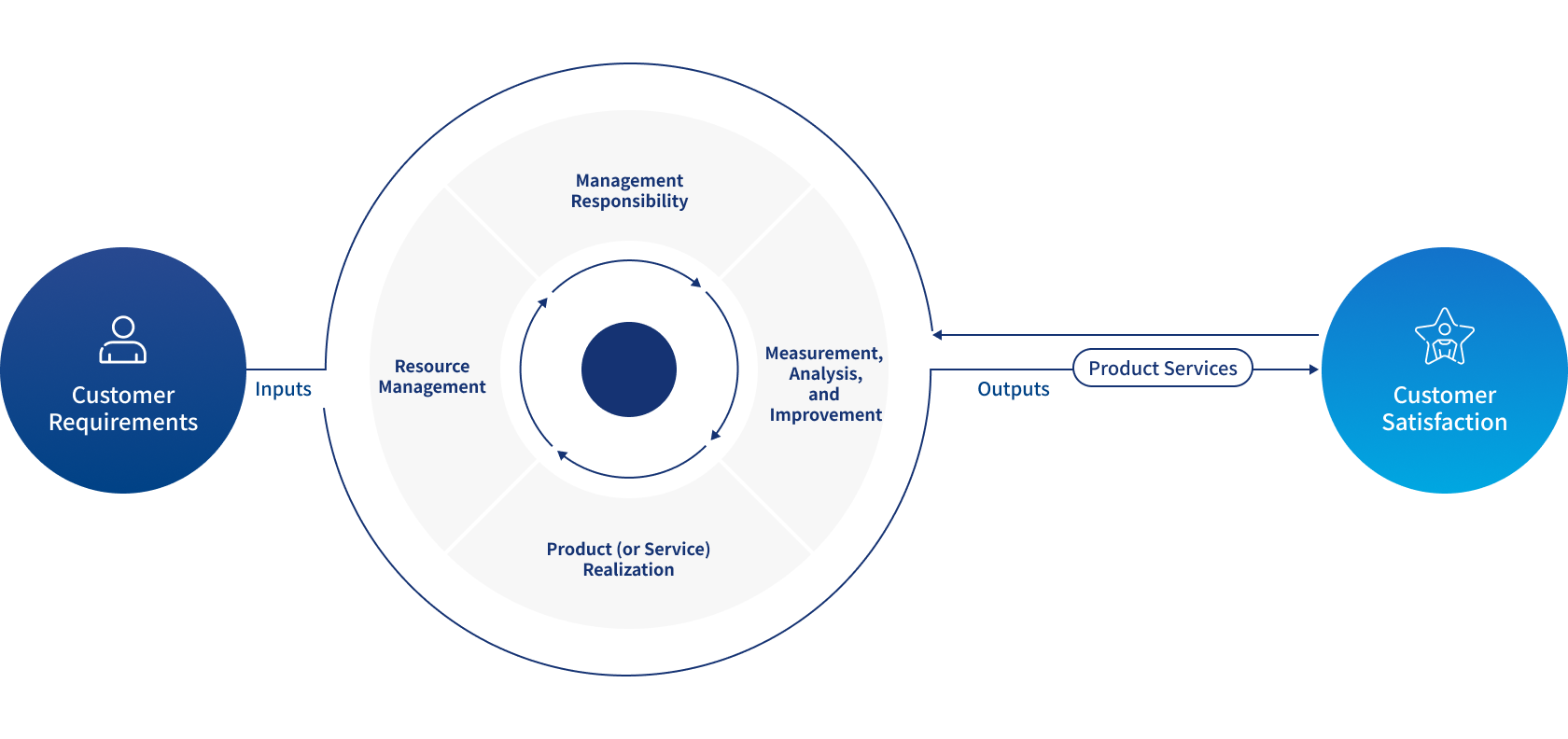

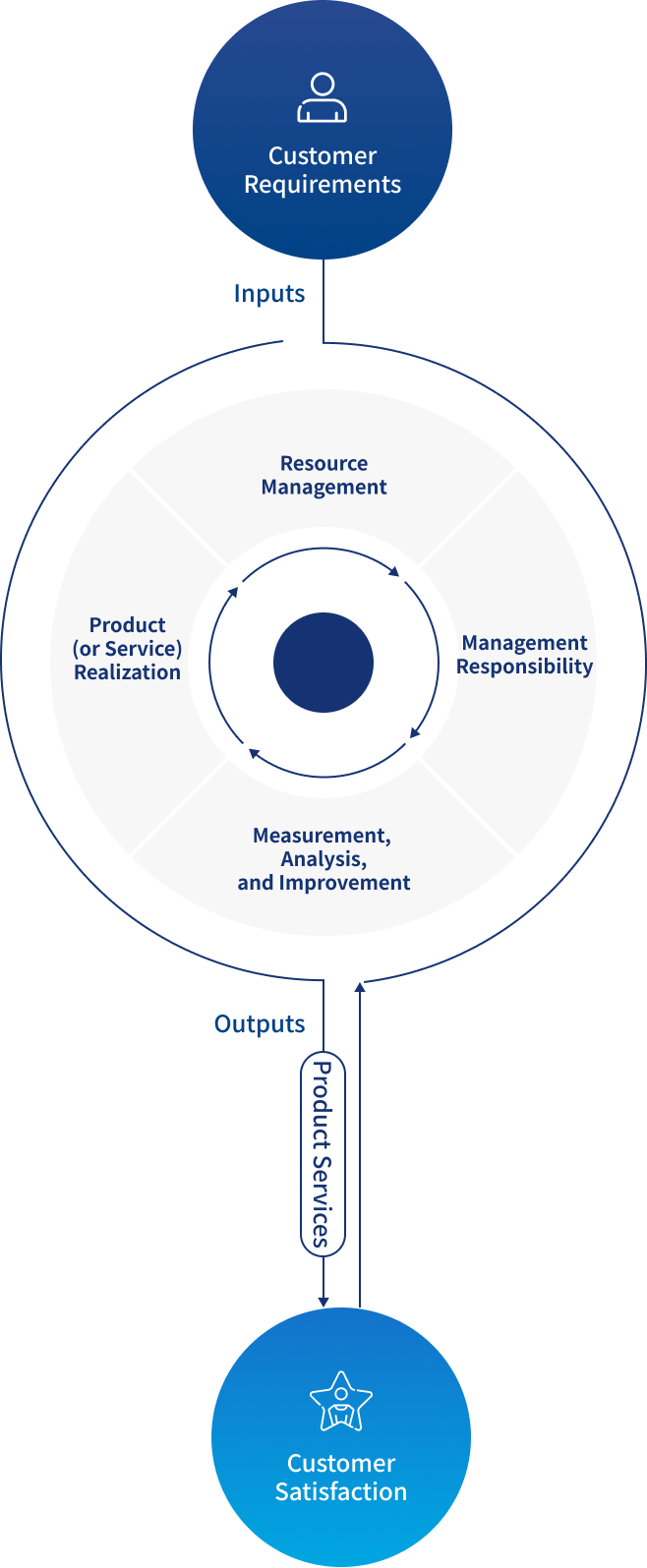

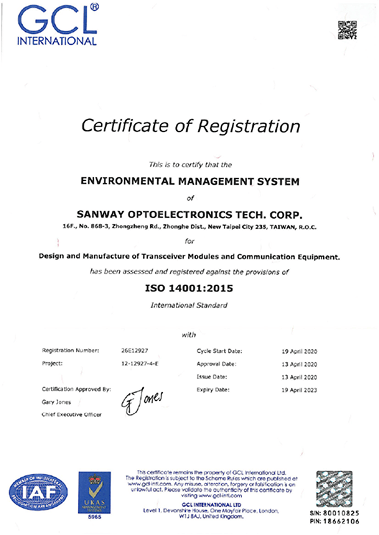

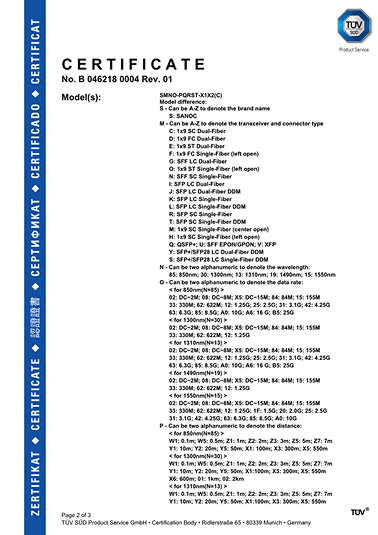

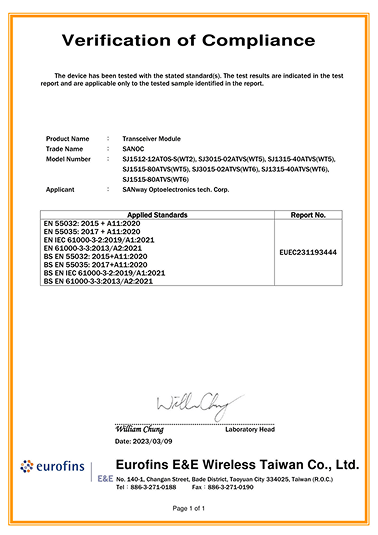

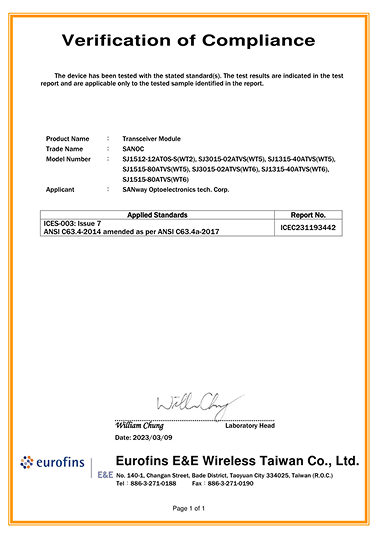

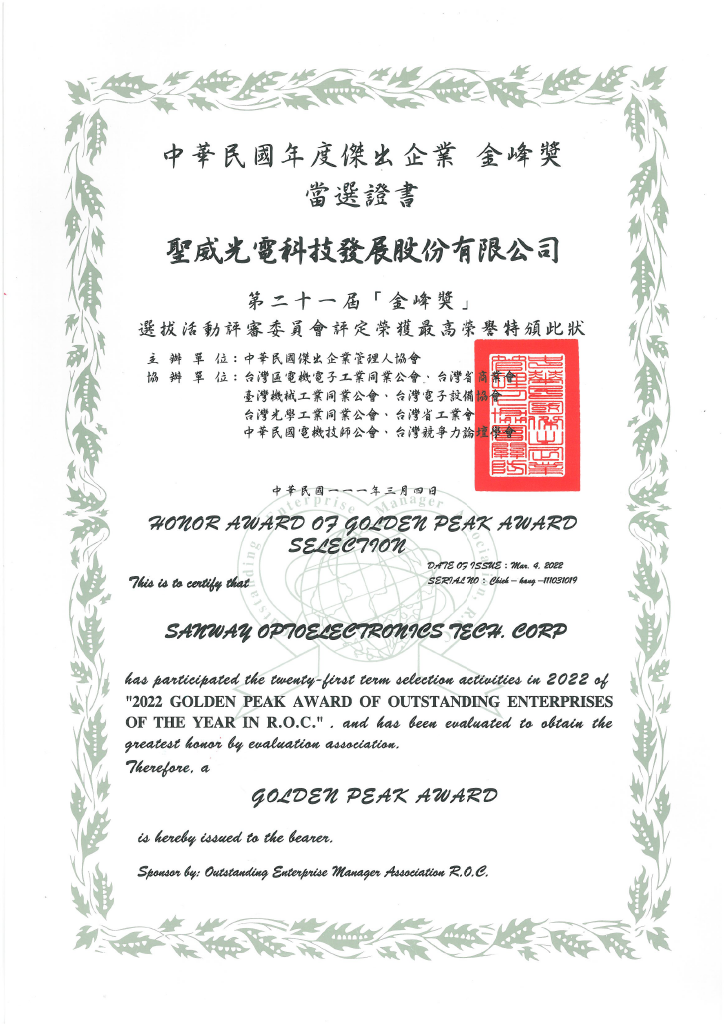

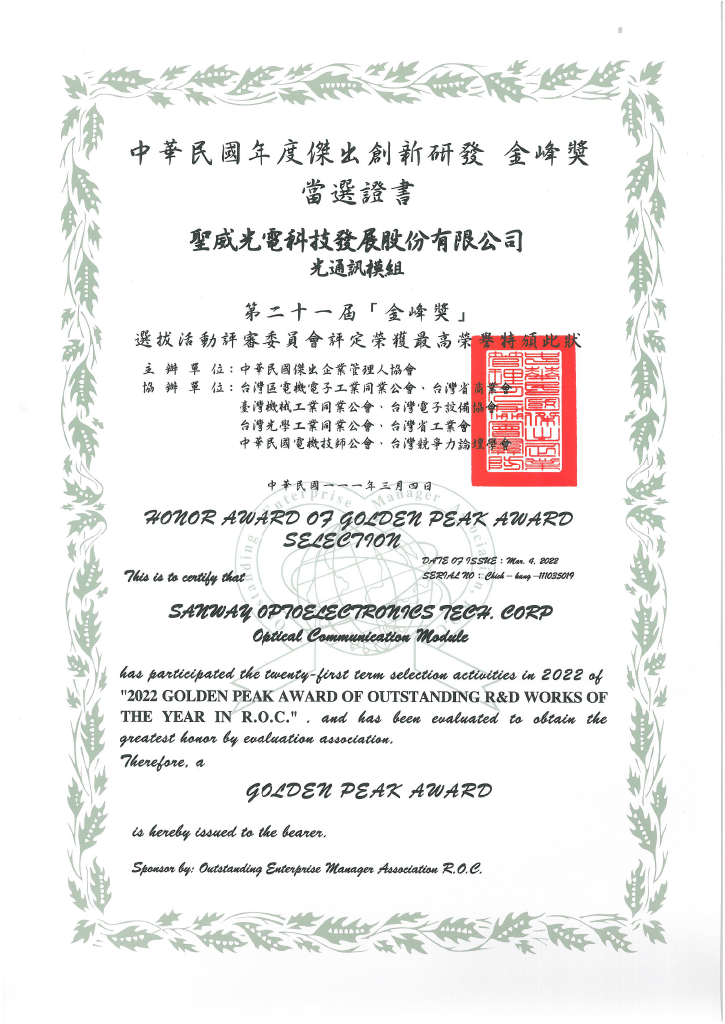

Quality Management System